Bright Industries is a trusted supplier and stockist of HCHCR D2 Tool Steel across India, known for its superior wear resistance, durability, and dimensional stability. D2 is a high-carbon, high-chromium tool steel that offers an excellent combination of toughness and hardness, making it ideal for precision tooling applications.

Bright Industries is a trusted supplier and stockist of HCHCR D2 Tool Steel across India, known for its superior wear resistance, durability, and dimensional stability. D2 is a high-carbon, high-chromium tool steel that offers an excellent combination of toughness and hardness, making it ideal for precision tooling applications.Key Features:

-

Exceptional Wear Resistance: Designed to withstand high-abrasion environments.

-

High Hardness: Can be heat treated to achieve 55–62 HRC hardness.

-

Dimensional Stability: Low deformation during heat treatment.

-

Good Corrosion Resistance: Performs well in mildly corrosive environments due to its high chromium content.

-

Air-Hardening: Eliminates the need for oil quenching and reduces risk of distortion.

Applications:

HCHCR D2 steel is suitable for various demanding industrial uses, including:

-

Cold work applications like trimming, thread rolling, and blanking dies.

-

High-precision cutting tools for sheet metals up to 12 mm thickness.

-

Forming and stamping tools for materials up to 6 mm thickness.

-

Ideal for threading rolls, shear blades, and metal-forming dies.

-

Can be nitrided after special heat treatment to enhance surface hardness.

Why Choose Bright Industries?

Bright Industries delivers top-grade D2 tool steel with reliable technical support, consistent supply, and value-added services like cutting and machining on request.

-

Bright Industries is a leading supplier and stockist of HCHCR D3 Tool Steel in India. D3 is a high-carbon, high-chromium ledeburitic steel known for its excellent wear resistance, hardness, and dimensional stability. It is ideal for precision tooling applications that demand strength and surface durability.

Bright Industries is a leading supplier and stockist of HCHCR D3 Tool Steel in India. D3 is a high-carbon, high-chromium ledeburitic steel known for its excellent wear resistance, hardness, and dimensional stability. It is ideal for precision tooling applications that demand strength and surface durability.Key Features:

-

12% Chromium Content: Offers superior hardenability and resistance to wear and abrasion.

-

High Wear Resistance: Perfect for long production runs and high-friction operations.

-

Air-Hardening Steel: Reduces risk of distortion during hardening.

-

Good Toughness and Edge Retention: Ensures longevity of cutting edges in heavy-duty applications.

Applications:

HCHCR D3 tool steel is widely used in cold work processes, including:

-

Cutting tools for sheet materials up to 4 mm thickness.

-

Trimming and blanking dies for paper, plastics, and thin metal sheets.

-

Rotational and shear cutting edges for sheets up to 2 mm thickness.

-

Precision dies where high compressive strength and sharpness retention are essential.

Why Choose Bright Industries?

At Bright Industries, we provide premium quality D3 steel, ensuring consistent performance and customer satisfaction. With expert guidance, reliable stock, and precision cutting services, we help manufacturers get the most out of their tooling materials.

-

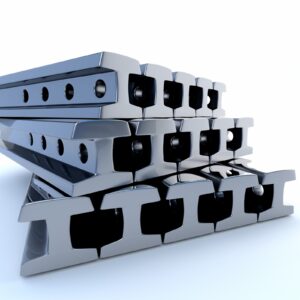

Tool & Die Steels

Tool & Die Steels are high-performance steels designed for durability, hardness, and resistance to wear—ideal for cutting tools, dies, and molds. These steels are engineered to withstand extreme conditions, offering excellent toughness and edge retention even under repeated stress and high temperatures.

Tool & Die Steels are critical for manufacturing processes that involve metal forming, machining, and precision tooling. Their unique combination of hardness and toughness ensures long service life and consistent performance, reducing maintenance needs and downtime in demanding industrial environments.

At Bright Industries, we provide tool & die steels that meet the highest standards for quality and performance, tailored to the specific needs of your production processes.